Backshop Report

Project 4259

By Mel Agne

This project deals with a methodology of installing Digitrax decoders in Athearn hood units, that I find appealing for several reasons. First of all, the DH-140 decoder features a detachable wire harness via a low profile header connector. This makes it very easy to replace in the event of failure, with no need to de-solder any connections. Unfortunately, this still involves disassembly of the locomotive, and if you like to detail yours like I do, this can be a dreaded thought. I wanted to try to utilize the removable dynamic brake housing as a way to access the decoder, so that if replacement were necessary it would not require disassembly of the unit. As it turns out, this is easy to accomplish, and adds to the ease of installation. Another thing about this method that I like is the parallel between putting the decoder in the dynamic brake housing, and the idea that real dynamic brake housings hold electrical equipment that generate heat. Most of Athearn's second generation scale hood width GP and SD series locomotives feature this removable panel, regardless of dynamic brakes or not. Although I have not tested it on non-dynamic units, I would guess that this method would still be applicable. Our unit for this discussion is an Athearn GP-40-2, factory painted in the WM version of the Chessie System. Please note that I have already modified the nose and pilot, and that this discussion will not delve into super-detailing or painting, but will only discuss items relevant to the installation of the decoder and lighting.

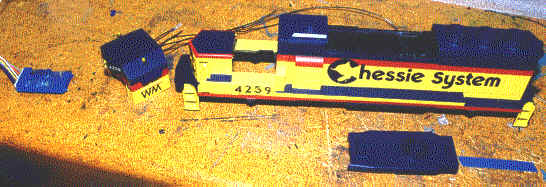

The above photo shows the decoder (left), cab and body with the

dynamic housing removed.

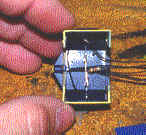

The first step is to enlarge the hole already present in the

panel recess. Using a Dremel tool, or sharp knife, cut the hole to the size

indicated by the white box above. Use the DH-140 decoder as a reference.

Remember, the goal here is to be able to mount the decoder face down (Digitrax logo on the

bottom, mostly flat side of the decoder on the top) with the connector facing

forward. Adjust the size of the hole until the decoder fits snugly over the hole.

Be careful not the cut the hole so large that the decoder falls down in. You

can test your success by trying to put the dynamic brake housing back on. It must

snap into place with the decoder inside without bulging or lifting up.

Because the DH-140 is an FX style decoder, I wanted to make use

of all of the lighting features. This means my unit will have front and rear lights,

classification lights, and (as on the prototype for WM4259) roof mounted strobes.

I choose to install the headlight bulbs directly in the holes

provided by Athearn for the headlight lenses. The 12 volt bulbs must be wired in

series so as not to generate so much heat that they melt the holes that they are in.

The roof top strobes are T-3/4 LED's mounted directly on the roof. The LED's

are wired in Parallel with a 1K resistor feeding them. Keep in mind that the Blue

wire from the decoder (light common) is actually the V+ from the decoder, which means that

all of the decoder functions are really ground paths. Be sure to wire your LED's up

in such a way the the Anode goes to the blue wire. The resistor can be before or

after the LED's in the circuit. The Digitrax manuals provide answers to your

questions about LED and lamp wiring if you have any. When finished this step, you

should have 3 wires sticking out. A common (that will go to the V+ blue wire), one

for the headlights, and one for the strobe lights.

Next, install the cab (but don't put in on all the way yet) and

feed the wires from the cab through the rectangular hole at the front of the dynamic brake

cavity. This hole IS used by the housing, but is large enough to accommodate our

wiring.

If your going to have operating class lights, and like to use

T-3/4 red LED's like I do, then you will need to drill out the class light locations with

a number 50 drill bit.

The T-3/4 LED's are pretty small, and a bit of a challenge to

install, but a drop of super glue will hold them in nicely. Make sure you glue them

in in such a way that the polarity of each is on the same side. This will make

wiring a bit easier.

First, snap the cab on all the way if you haven't done so

already (you need to consider what your going to do with window glazing, weathering, dull

coating etc, before you do this, as the cab will not be removable after this step).

Run a wire from the Anode of the front class light LED's to the common (blue wire)

connecting point already established in the cab roof. Connect another wire to the

Cathode side of the LED's (don't forget the 1K resistor somewhere) and route it through

the front dynamic brake housing rectangular hole.

Do the same for the rear class lights. The resistor used

is clearly visible in this photo.

Next, add the rear headlights (wired in series and mounted in

the holes). You could use a single bulb and the Athearn lenses if you prefer.

Configure the wires as you did in the front, and you will have 3 wires sticking through

the rear dynamic brake housing panel rectangular hole.

Prepare the chassis according to established procedures (motor

isolated from frame, trucks wired, Athearn headlight bracket removed), and leave plenty of

wire loose.

Next, position the body over the chassis, and bring the motor

and truck wires up through the hole in the roof. Trim all the wires to reasonable

lengths, and connect the decoder using Digitrax instructions. Remember that you have

two common (V+ Blue wire) feeds from the front and rear of the shell to connect to the

blue wire. The DH-140 only has 4 functions, so you will have to decide which one

does what, but I choose White - Front headlight, Yellow - Rear Headlight, Green - Roof

strobes, and Purple - Class lights (both front and rear connected together).

Alternately, you could connect the rear class lights to the white wire with the front

headlight, and the front class lights to the yellow wire with the rear headlight, so that

the traditional display of red markers on the rear while going forward with the front

headlight on would be evident. Or, you could connect the front class lights directly to

the purple, leaving the rear class lights connected to the front headlight (white)

wire. This makes for a neat effect when your locomotive is operating as a pusher

facing backwards - Just like on Sandpatch! Or rather I should say just like they

USED to, before CSX ripped out all the class lights!

Make sure you have the body on all the way now. Begin

stuffing all those wires (which you properly soldered and covered with heat-shrink tubing)

into the body cavity. Pushing them forward with tweezers seems to work well.

Once stuffed, they should allow the decoder to rest in place

like it did when you were test fitting it earlier. Don't put the housing back on

yet. The dynamic brake housing looks like it might get loose with too much

installing and removing, so don't test fit yet.

Go ahead and test run your engine. Take a moment to

program the decoder, and get those strobe lights flashing the way they should. Run

the engine with all of the functions turned on and watch for excessive heat, or mechanical

problems. While it's making some laps around your layout, you can do the next step

which is optional.

Since decoders do generate some heat, I thought it might be

nice if that heat could escape easily. I had a 48" fan left over from a

Life-Like Proto 2000 GP-18 that is slightly different from the one included on the Athearn

model, but the thought of a little fan blade that will really spin (if you blow on it),

and the ability of the decoder to vent heat up through the fan (just like the real thing!)

over ruled any desire for 100% prototypicallity. Besides, who says somebody in

Cumberland didn't have to replace the fan on 4259 at some point in it's life? Don't

think for a minute that the shops wouldn't substitute a different model fan if they had

to.

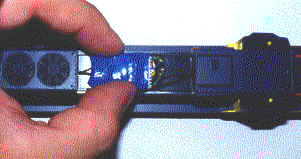

After removing the cast-on fan, go ahead and fetch your engine

(which you left testing on the layout) and put the dynamic brake housing on. The

decoder is now clearly visible through the hole. If you made the hole the right

size, your replacement fan will now press-fit, and it won't require any glue.

Here we see WM 4259 rolling out of the Moose Valley's Berkeley

shops, after being serviced and upgraded with what the Moose Valley refers to as

"Dynamic Consist Control" (Sounds more railroady than DCC). That little

fan that spins when you blow on it will keep that nice Digitrax DH-140 cool and

ventilated, and if it ever does fail, it will only take 1 minute to replace it without

disassembling your entire model.

Happy Railroading!